When it comes to motorcycle performance, few systems have as much impact as the fuel delivery method. The eternal debate between carburetors and fuel injection systems continues to spark passionate discussions among riders of all experience levels. As a rider, understanding the differences, advantages, and maintenance requirements of each system can help you make informed decisions about your motorcycle's care and performance.

At Carolina Cycle, we've been servicing both carbureted and fuel-injected motorcycles since 1970. Our decades of experience have given us unique insights into the maintenance requirements and performance characteristics of both systems. Whether you're maintaining a classic carbureted bike or a modern fuel-injected machine, proper maintenance with quality OEM parts is essential for reliability and performance.

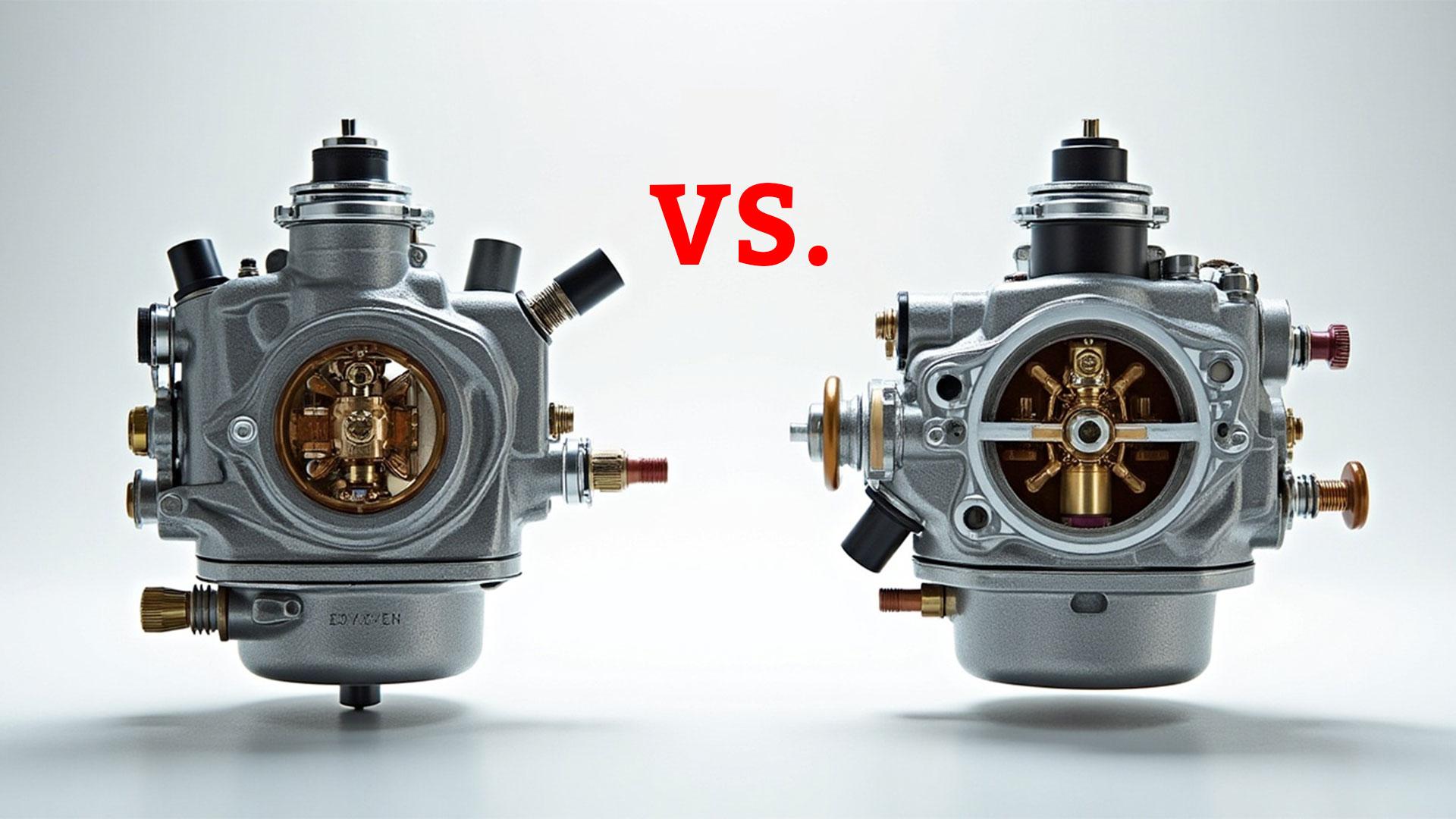

1. Understanding the Basics: Carburetors vs. Fuel Injection

Before diving into maintenance specifics, let's clarify how each system works and their inherent advantages and limitations.

How Carburetors Work

A carburetor is essentially a mechanical device that mixes air and fuel in the proper ratio for combustion. It operates on the venturi principle – as air flows through a narrowed section of the intake, it creates a pressure drop that draws fuel into the airstream.

Key components of a motorcycle carburetor include:

- Float bowl: Stores fuel at a constant level

- Jets: Precisely sized orifices that meter fuel flow

- Needle and seat: Control fuel entry into the float bowl

- Slide or butterfly valve: Controls airflow volume

- Choke: Enriches the fuel mixture for cold starts

Carburetors require no electrical components to function, making them simpler in some ways but requiring more manual adjustment to optimize performance across different conditions.

How Fuel Injection Works

Fuel injection systems use electronic controls and pressurized fuel delivery to provide precise metering of fuel. Modern systems are managed by an Engine Control Unit (ECU) that continuously adjusts the fuel mixture based on multiple sensor inputs.

Essential components of a motorcycle fuel injection system include:

- Fuel pump: Creates pressure in the fuel line

- Injectors: Electronically controlled valves that spray fuel

- Throttle bodies: Control airflow into the engine

- Various sensors: Monitor engine temperature, throttle position, oxygen content, and more

- ECU: The "brain" that processes sensor data and controls the injectors

Fuel injection offers greater precision and adaptability to changing conditions but requires proper electrical function and more complex diagnostic procedures when issues arise.

2. Advantages and Disadvantages of Each System

Understanding the strengths and weaknesses of each fuel system helps inform maintenance priorities and performance expectations.

Carburetor Advantages

- Mechanical simplicity: Fewer components to fail

- No electrical dependence: Will run without a battery or electrical system

- User adjustability: Can be tuned trackside with basic tools

- Classic character: Many riders appreciate the distinctive feel and sound

- Lower initial cost: Generally less expensive than fuel injection systems

Carburetor Disadvantages

- Temperature sensitivity: Performance varies with ambient conditions

- Altitude limitations: Requires rejetting for significant elevation changes

- Less precise fuel metering: Can waste fuel and increase emissions

- Manual enrichment: Requires choke operation for cold starts

- Multiple carbs: Multi-cylinder bikes require synchronization

Fuel Injection Advantages

- Consistent performance: Automatically adapts to temperature, altitude, and humidity

- Improved fuel economy: More precise metering reduces waste

- Better cold starting: No manual choke required

- Smoother throttle response: Especially at low speeds and during transitions

- Reduced emissions: More complete combustion and better control

Fuel Injection Disadvantages

- Electrical dependence: Requires functioning electrical system

- More complex diagnostics: Specialized tools often needed

- Higher component cost: Replacement parts generally more expensive

- Less field-serviceable: Limited roadside repair options

- Technical complexity: More specialized knowledge required for troubleshooting

3. Essential Maintenance for Carbureted Motorcycles

Carburetors require regular maintenance to keep them performing optimally. Here's what you need to know about keeping your carbureted bike running smoothly.

Regular Cleaning and Inspection

Carburetors gradually accumulate deposits from fuel that can clog jets and passages. Regular cleaning prevents performance issues.

- Cleaning frequency: Every 5,000-10,000 miles for most riders, more frequently if using ethanol-blended fuels

- Visual inspection: Check for fuel leaks, damaged vacuum lines, and throttle cable condition

- Float level: Verify proper setting according to service manual specifications

- Jet inspection: Ensure jets are clear and undamaged

When cleaning carburetors, using genuine OEM parts for any replacements ensures proper fit and function. For example, Honda jets are manufactured to precise specifications that aftermarket parts may not match, leading to performance issues.

Synchronization for Multi-Carburetor Systems

Motorcycles with multiple carburetors require periodic synchronization to ensure smooth operation.

- Symptoms of poor sync: Rough idle, hesitation, poor throttle response

- Synchronization frequency: Every 6,000-12,000 miles or whenever carbs are serviced

- Tools required: Vacuum gauges and adjustment tools specific to your motorcycle

- Procedure overview: Balancing the vacuum or airflow between multiple carburetors

Proper Jetting and Tuning

Carburetors may require rejetting for optimal performance based on modifications, altitude, or seasonal changes.

- Common jet changes: Main jet, pilot jet, needle position

- Symptoms of incorrect jetting: Poor fuel economy, sluggish performance, backfiring

- Factors affecting jetting: Air filter modifications, exhaust changes, altitude, temperature

- OEM vs. aftermarket jets: OEM jets provide consistent quality and sizing accuracy

Float Bowl and Gasket Maintenance

The float bowl seals and gaskets prevent fuel leaks and ensure proper fuel level.

- Replacement intervals: Every carburetor service or when leaks occur

- Material quality: OEM gaskets use appropriate materials for fuel resistance

- Float valve inspection: Check for wear that could cause flooding

- Bowl drain procedure: Regularly drain to remove water and contaminants

Using OEM gaskets is particularly important as they're designed with the correct materials and dimensions for a proper seal. Generic gaskets often lead to leaks or premature degradation from fuel exposure.

4. Fuel Injection System Maintenance

While generally more reliable than carburetors, fuel injection systems require their own maintenance regimen to ensure optimal performance.

Fuel Pressure System

The pressurized fuel delivery system is critical to proper injection operation.

- Fuel pump: Listen for proper operation when turning the key (a brief whirring sound)

- Pressure regulator: Ensures consistent fuel pressure to injectors

- Fuel filter: Replace according to manufacturer intervals (typically 10,000-20,000 miles)

- Pressure testing: Diagnostic procedure to verify system integrity

Injector Cleaning and Testing

Fuel injectors can develop deposits that affect spray patterns and flow rates.

- Cleaning intervals: Every 15,000-25,000 miles depending on fuel quality

- Professional service: Ultrasonic cleaning with specialized equipment

- Flow testing: Verifies balanced fuel delivery across all cylinders

- OEM replacement: When cleaning doesn't restore proper function

Genuine OEM injectors ensure proper flow rates and spray patterns for your specific motorcycle model. Aftermarket injectors may not match the exact specifications required for optimal performance.

Sensor Maintenance and Testing

Fuel injection relies on multiple sensors to make fuel delivery decisions.

- Oxygen sensors: May require replacement every 30,000-40,000 miles

- Throttle position sensor: Check for smooth operation and proper readings

- Temperature sensors: Verify accurate temperature reporting

- Intake air sensors: Clean or replace when dirty

ECU and Electrical System Care

The electronics controlling fuel injection require their own maintenance.

- Battery condition: Maintain proper voltage for system operation

- Wiring harness: Inspect for chafing, corrosion, or damage

- Ground connections: Clean and secure all ground points

- Diagnostic scanning: Periodic checks for stored error codes

For detailed fuel injection diagnostics and service, our motorcycle repair services include computer analysis and OEM-specified testing procedures.

5. OEM Parts Critical for Fuel System Reliability

Whether maintaining a carburetor or fuel injection system, using genuine OEM parts is crucial for several reasons:

Carburetor OEM Components

- Jets and needles: Manufactured to precise dimensions for proper fuel metering

- Float valves: Correct materials and sealing surfaces to prevent leaks

- Gaskets and O-rings: Proper fuel resistance and compression characteristics

- Throttle slides: Exact dimensions for smooth operation

- Diaphragms: Correct flexibility and durability for consistent performance

Fuel Injection OEM Components

- Fuel injectors: Matched flow rates and spray patterns for your engine

- Fuel pump assemblies: Correct pressure specifications and durability

- Sensors: Calibrated specifically for your motorcycle's ECU

- Throttle bodies: Precise bore dimensions and throttle plate movement

- O-rings and seals: Designed for high-pressure fuel system requirements

6. Converting Between Systems: Considerations

Some riders consider converting from carburetors to fuel injection or vice versa. Here's what you should know:

Carburetor to Fuel Injection Conversion

- Complexity: Requires significant modifications to intake, fuel delivery, and electrical systems

- Cost factors: Typically $1,000-$3,000 depending on the motorcycle

- Performance gains: Improved cold starting, altitude adaptation, and often better fuel economy

- Considerations: May affect the classic character of vintage motorcycles

Fuel Injection to Carburetor Conversion

- Practicality: Rarely practical on modern motorcycles due to integrated designs

- Reasons: Usually only done for specialized racing applications or extreme customization

- Challenges: May require extensive intake manifold modifications

- Emissions compliance: Often results in non-compliance with emissions regulations

7. Common Problems and Troubleshooting

Even with proper maintenance, fuel delivery issues can arise. Here's how to identify and address common problems:

Carburetor Troubleshooting

- Flooding: Excessive fuel delivery usually caused by float issues or dirty needle valve

- Poor idle: Often related to pilot jet clogging or incorrect adjustment

- Hesitation: May indicate main jet issues or improper needle position

- Hard starting: Could be choke malfunction or improper float level

- Surging: Often caused by vacuum leaks or carburetor synchronization issues

Fuel Injection Troubleshooting

- Check engine light: Always the first indicator of system issues

- Rough idle: May indicate dirty injectors or sensor problems

- Poor fuel economy: Often related to faulty oxygen sensors or fuel pressure issues

- Hard starting: Could be fuel pump, pressure regulator, or coolant temperature sensor

- Hesitation: May indicate throttle position sensor issues or clogged injectors

8. Seasonal Considerations for Fuel Systems

Different seasons present unique challenges for motorcycle fuel systems.

Winter Storage Preparation

- Carburetor preparation: Drain float bowls or add fuel stabilizer

- Fuel injection care: Fill tank and add stabilizer to prevent corrosion

- Battery maintenance: Use a tender to maintain fuel injection systems

- First spring start: Special procedures to ensure proper operation

Summer Heat Management

- Vapor lock: More common in carbureted bikes in extreme heat

- Fuel volatility: May require jet changes in carburetors for very hot climates

- Cooling system interaction: Affects fuel delivery in both systems

- Heat soak: Can cause hard restarting in certain fuel-injected motorcycles

9. Frequently Asked Questions

How often should I rebuild my motorcycle's carburetor?

For regularly ridden motorcycles, a complete carburetor rebuild is typically recommended every 15,000-20,000 miles. However, riding conditions and fuel quality can significantly impact this interval. Signs that a rebuild is needed include rough idle, poor throttle response, fuel leaks, or difficulty starting. Always use an OEM rebuild kit with genuine Honda, Kawasaki, Suzuki, or Yamaha parts to ensure proper fit and material compatibility.

Why does my fuel-injected motorcycle run rough when cold?

Cold running issues in fuel-injected motorcycles are commonly caused by faulty temperature sensors that prevent proper cold enrichment. The ECU relies on accurate temperature data to adjust fuel delivery. Other potential causes include fuel pressure problems, injector deposits, or failing oxygen sensors. Diagnostic scanning can identify specific error codes and sensor readings to pinpoint the issue.

Is it worth upgrading to performance carburetors or injectors?

For most street riders, OEM carburetors or injectors optimized with proper tuning provide the best balance of performance, reliability, and rideability. Performance upgrades are most beneficial for race applications or heavily modified engines where fuel delivery becomes a limitation. For mild performance improvements, focus first on proper maintenance and tuning of your stock components before considering expensive upgrades.

Can I use fuel additives to clean my fuel system instead of servicing it?

While fuel additives can help maintain clean fuel systems and remove minor deposits, they aren't a replacement for proper service. Additives work gradually and can't address mechanical issues like worn float needles, damaged O-rings, or electrical problems in fuel injection systems. They're best used as a preventative measure between regular maintenance intervals.

How do I know if my carburetor jets need changing?

Signs that your carburetor needs rejetting include poor fuel economy, black smoke (too rich) or popping in the exhaust (too lean), sluggish acceleration, or rough idle that doesn't improve with adjustment. Changes in altitude, major air filter modifications, or exhaust system changes often necessitate rejetting. Consult your service manual for proper jet sizing or contact our experienced technicians for professional advice specific to your motorcycle.

What's the lifespan of fuel injectors?

Quality OEM fuel injectors typically last 50,000-100,000 miles when properly maintained with clean fuel and regular filter changes. Factors that reduce lifespan include poor fuel quality, ethanol content, extended storage without stabilizer, and electrical system issues that cause improper operation. Regular injector cleaning service every 20,000-30,000 miles can significantly extend their functional life.

Conclusion

Whether your motorcycle features a traditional carburetor or modern fuel injection, understanding the maintenance requirements and using quality OEM parts is essential for reliability and performance. Each system has distinct advantages and challenges, but both can provide excellent service when properly maintained.

For carbureted motorcycles, regular cleaning, proper adjustment, and quality replacement parts keep your fuel system delivering the right mixture under all conditions. Fuel-injected bikes benefit from clean fuel, proper electrical system maintenance, and periodic diagnostic checks to ensure all components are functioning correctly.

At Carolina Cycle, we've been providing riders with genuine OEM parts for Honda, Kawasaki, Suzuki, and Yamaha motorcycles since 1970. Our extensive inventory of motorcycle OEM parts includes everything needed to keep your fuel system in peak condition, whether you're maintaining a vintage carbureted classic or a modern fuel-injected sport bike.

Remember that investing in quality maintenance with genuine parts is always more cost-effective than dealing with roadside failures or performance issues. For assistance selecting the right components for your specific motorcycle model or to schedule professional fuel system service, contact our team of powersports experts today.

The debate between carburetors and fuel injection may continue indefinitely among enthusiasts, but one thing remains clear – both systems deliver their best performance when maintained with care, knowledge, and quality parts. Ride safe and enjoy the journey!